PROJECTS

Design and manufacturing of:

- Instrumentation for low-gravity experiments,

- Control Systems based on sensors using optical planar guides.

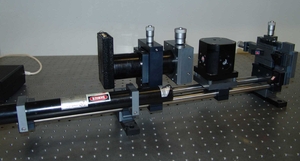

1.1 - MULTIDIRECTIONAL FIBER OPTICS HOLOGRAPHIC INTERFEROMETER (MHOI)

This unique (6-holographic channels) instrument had been designed and manufactured for ESA/ESTEC to meet ALENIA (prime contractor) and GENOA UNIVERSITY theoretical requirements, in order to investigate the boundary-layer phenomenology of crystals growing in low-gravity conditions.

The restricted dimensions (650x400x350 mm, less than half a Columbia rack) of the instrument forced us to develope a complex lay-out to contain six He-Ne lasers, shutters, plate holders, and a number of expressely designed parts, among which:

- Six single-mode, wave-front division, fiber couplers to obtain six couples of coherent object-reference beams to be expanded, collimated, and crossed in a:

- Cell with 12 optical windows containing the crystal in its solution,

- Small (60x45x30 mm) compact and rugged XYZ positioneers, with differential screws builded in the guiding columns, to obtain the wanted object/reference power ratio in each coherent couple,

- Optical and mechanical means, to avoid Fabry-Perot extracavity effects at the coupler's front surface and at the input end of the 12 collimators.

1.2 - MHOI POWER METER (GENOA UNIVERSITY)

A dedicated instrument to detect the instant intensity ratio of object-to-reference beams, in each of the six coherent couples of 1.1. interferometer.

1.3 - DIFFRASOR (ASI, Italian Spatial Agency / GENOA UNIVERSITY)

A new approach to the study of boundary layer in growing crystals, based on refractive index gradient variation measurements.

1.4 - LARGE SURFACE INCOHERENT ILLUMINATOR IN GABRIEL PROJECT

(Gravity Assessment for Boiling Research and Investigation with ELectric field. [ESA], prime contractor: SWEDISH SPACE CORP., contractor: FERRARI SPA)

The device has two illuminating surfaces (80x59 mm) each employing 168 LED (5 mm, modified); the circuitry minimizes the power consumption and compensates for the differences in emissivity of the individual sources.

The experiment had been conducted with success from Esrange (Sweden) spatial base May 3, 1996.

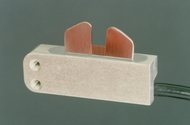

2.1 - WEFT DETECTOR IN AIR-JET LOOMS, MTX-0416

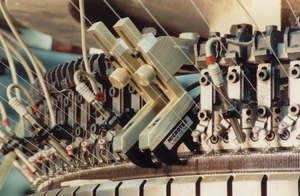

2.2 - NEEDLE CHECK SYSTEM, NCS-02,

to analyse the possible deformations of needles in knitting machines at work (International Patent)

Both 2.1 and 2.2 are textile industry applications making use of sensors made from LED and detectors coupled to borosilicate or plastic guides leading to uniform optical field in the intermediate free sensing space. Our design and manufacturing includes the optical guides ( with their mfrng tools ), the mechanical structure of the sensors and their positioning devices, the sensor assembling at optical coniugate points, and the microprocessor-based system electronics.

OTHER PROJECTS

3 - FIRST ITALIAN FIBER OPTICS NETWORKING OF AN INDUSTRIAL VEHICLE

(FIAT C.R.F, DIXIE)

4 - STRUCTURED LASER LIGHT PROJECTOR

(prototype, FIAT C.R.F)

5 - DEFORMATION SENSOR IN VEHICLES

(prototype, FIAT C.R.F)

6 - OPTICAL HAED FOR TRANSCLERAL OPHTHALMIC SURGERY

(S.RAFFAELE HOSP.MILAN, Lateral variable focusing distance from fibre probe end)

7 - LARGE-APERTURE, 4-LENSES, APLANATIC SYSTEM OF PLANAR GUIDES

Designed and manufactured in a prototype serie

8 - DEVICE FOR TESTING THE STATIC FATIGUE LIMIT OF LENGTHS OF OPTICAL FIBRES

(CSELT, TURIN)

9 - BAR CODE READER

(Savio Macchine Tessili, Side view detection in small cavities)